Advanced technologies to drive production

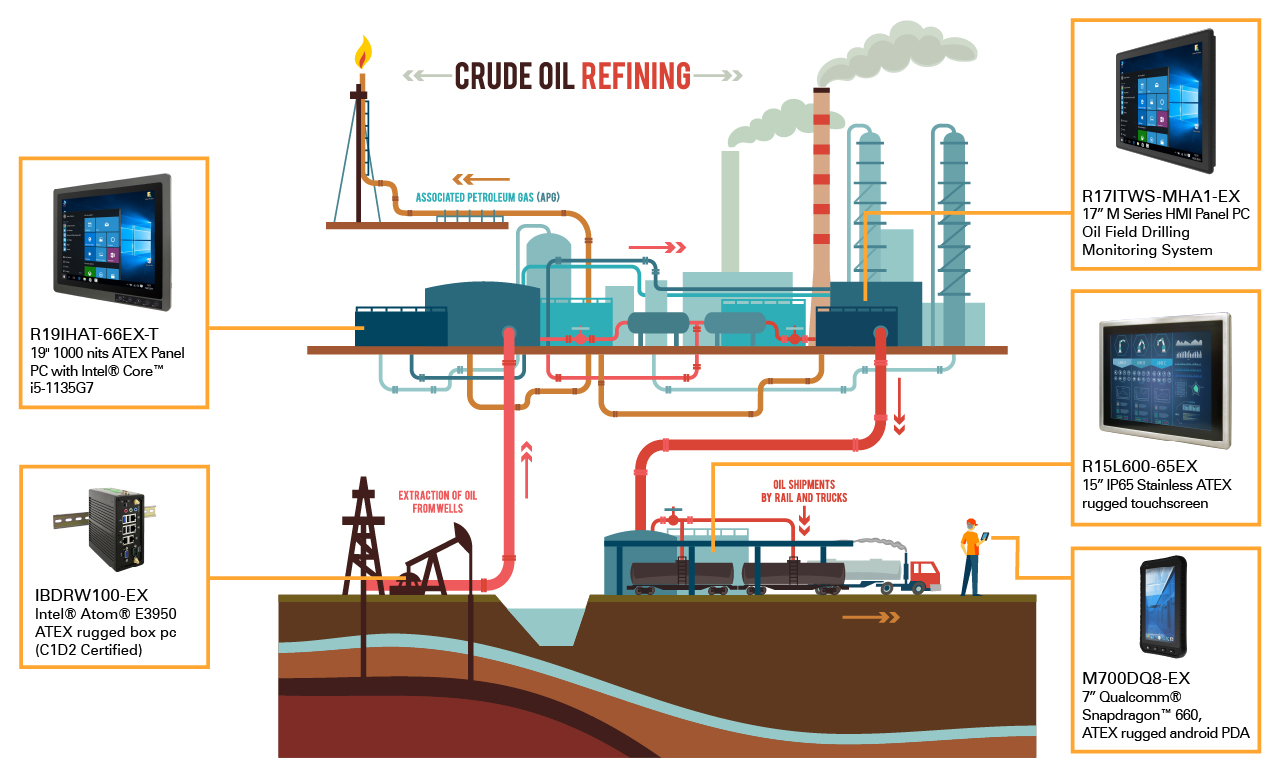

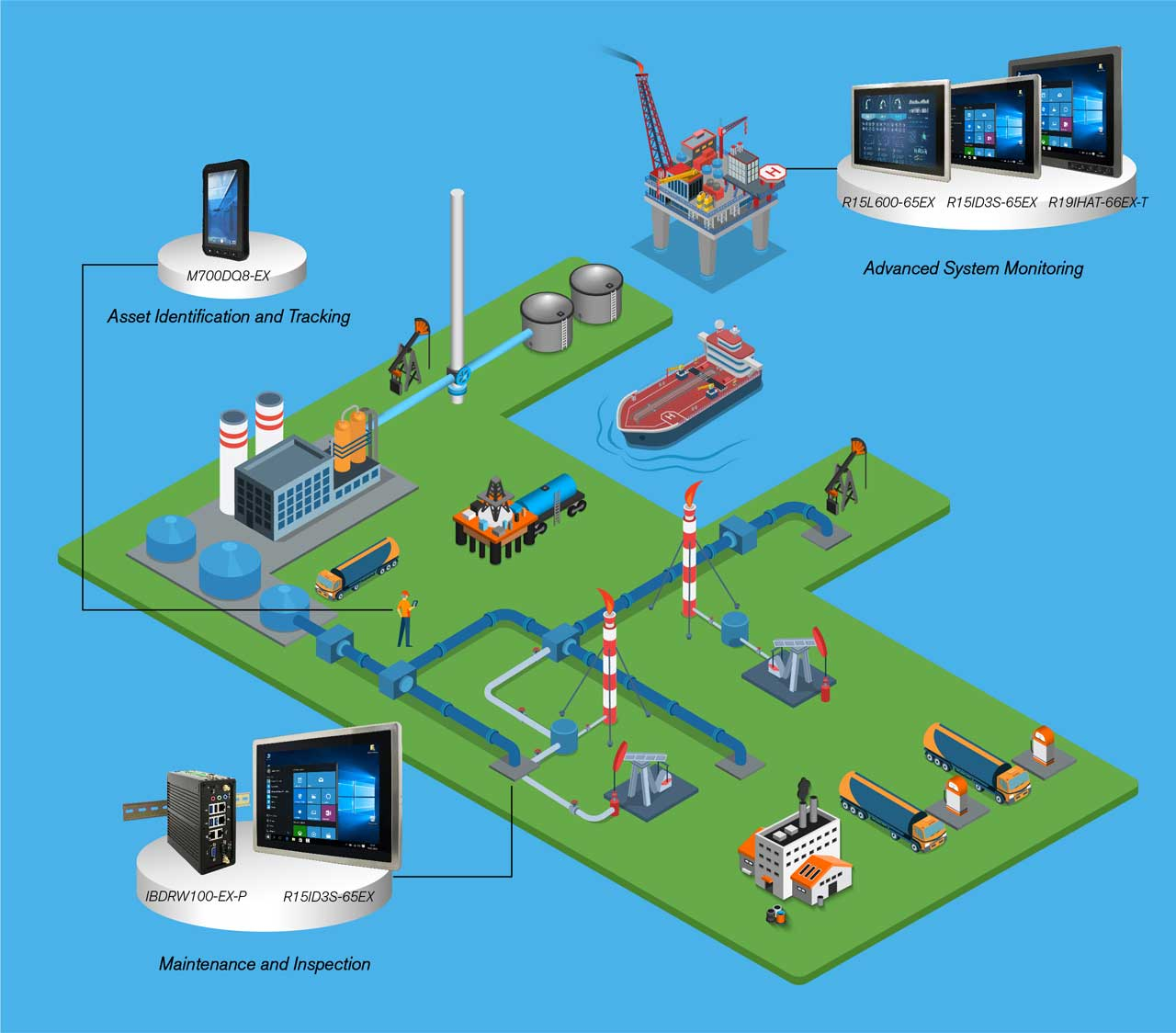

The oil & gas industry is one of the most dangerous and challenging work environments. Because the conditions are risky for both personnel and equipment, reliable and accurate monitoring is crucial to maintaining safe operations. Winmate offers Explosion-Proof panel computers for remote data collection, process visualization, and control. Secure technologies help to improve the productivity, safety, and efficiency of oil refineries. Effectively control processes to lower operation costs and gain more profit. Our computing solutions are deployed in refining and petrochemical applications and have helped many companies improve productivity, safety, and efficiency.

Winmate has technology know-how for the production and development of explosion-proof data processors.

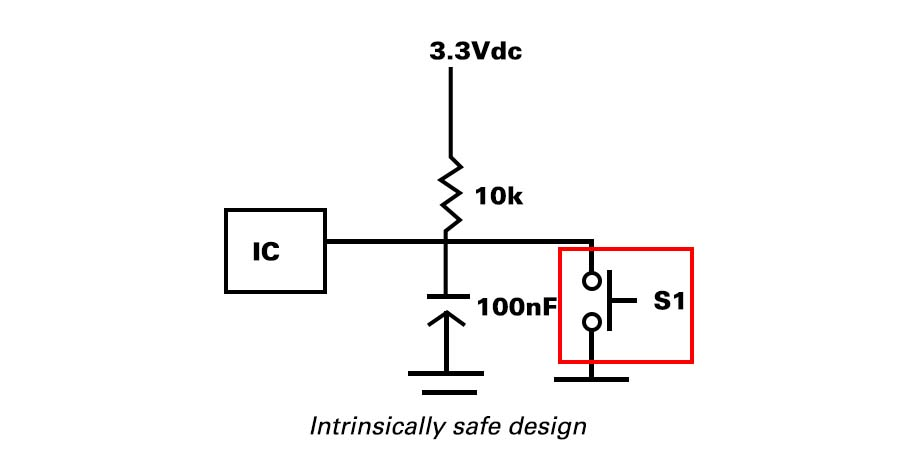

It is required by law and legislation by countries worldwide that electrical equipment must be designed and manufactured for safe use in environments or atmospheres that may be potentially flammable or explosive. These hazardous areas are flammable gases or vapors, flammable liquids, combustible dust, or ignitable fibers or flyings. At oil and gas production operations and facilities, these hazards and dangers are commonplace. Flammable or explosive substances may be present in varying quantities at all times, so fire and explosion protection and safety certifications for all electrical equipment used in these operations are mandatory.

Winmate explosion-proof solutions include:

Winmate's rugged mobile computers are built to last, reducing the total cost of ownership over time. Retailers, manufacturers, logistics companies, and field service organizations choose Winmate portable computers daily to improve daily operations.

Oil rigs and remote pipeline locations are some of the most dangerous and challenging work environments anywhere. Winmate rugged computers are designed for the environments of an oil refiner or a drilling rig and come with ATEX Zone2 and Class1 Division2 (C1D2) certifications. Winmate offers ATEX Zone 2 and Class 1 Division 2 (C1D2) certified panel computers, embedded processors, and industrial displays for remote data collection, process visualization, and control. Safe technologies help to improve the productivity, safety, and efficiency of oil refineries. Effectively control processes to lower operation costs and gain more profit. Our computing solutions are deployed in refining and petrochemical applications and have helped many companies improve productivity, safety, and efficiency.

|

|

Intrinsic Safety Schematic Design

|  |

| Non-Sparking Device

|

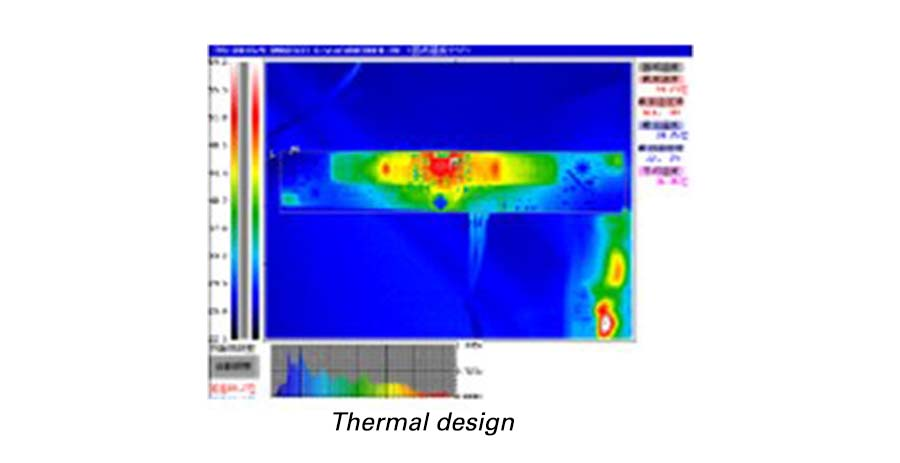

High Processing Power and Fanless Thermal System

|  |

| Suitable for Operations in Extreme Working Conditions

|

No-Air Potting Process

|  |

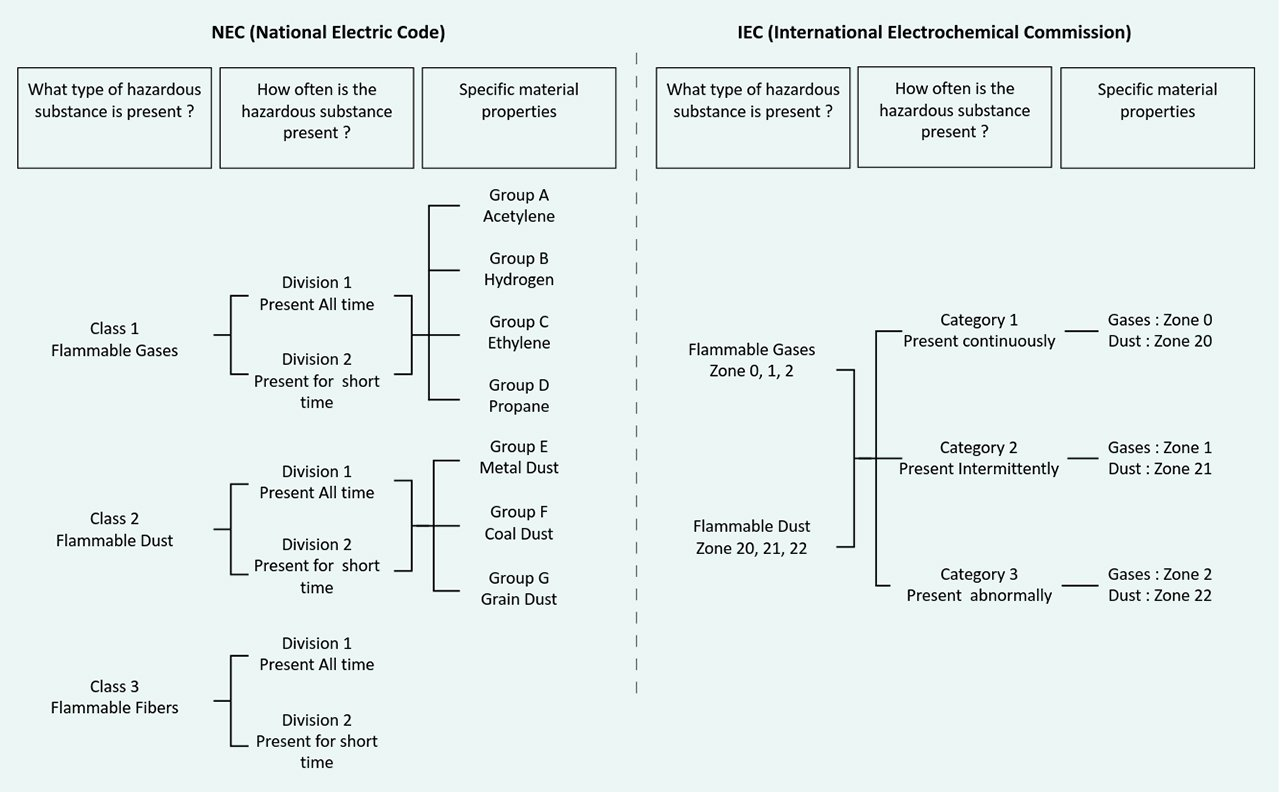

Safety and StandardsQuality Management SystemWinmate factory is UL and CSA certified with Quality Management System. Product Testing & CertificationsTo meet the safety qualification, Winmate offers ATEX and Class 1 Division 2 (C1D2) certified solutions for maintaining safe operations and collecting detailed, sensitive data in the remote rig and pipeline locations. Winmate generally uses both the North American National Electric Code (NEC) and the European ATEX directive for the equipment classification. | |

According to OSHA, NEC defines hazardous locations as those areas where fire or explosion hazards may exist due to flammable gases or vapors, flammable liquids, combustible dust, or ignitable fibers or flyings. NEC classified hazardous locations in three ways; type, condition, and nature.

IEC defines the flammable gases and vapors, and then combustible dust, each of these types is assigned into three different zones, and each zone then requires equipment built for category I, II, or III.

M700 Series Rugged Tablet | ATEX Panel PC | M Series HMI |

ATEX Display | M Series Box PC | DIN Rail Box PC |