Automated Production Line for Beverage

Background

With the development of IoT, more machines and on-site devices need to be connected to the Internet. Faced with increasing data to be uploaded to the cloud, how can we ensure quick access while reducing the pressure of cloud computing?

In different industrial production processes, due to various brands for automated devices, diverse industrial interfaces, non-uniform protocols and poor openness, data collection is challenging. Then how can we deal with it?

Solution

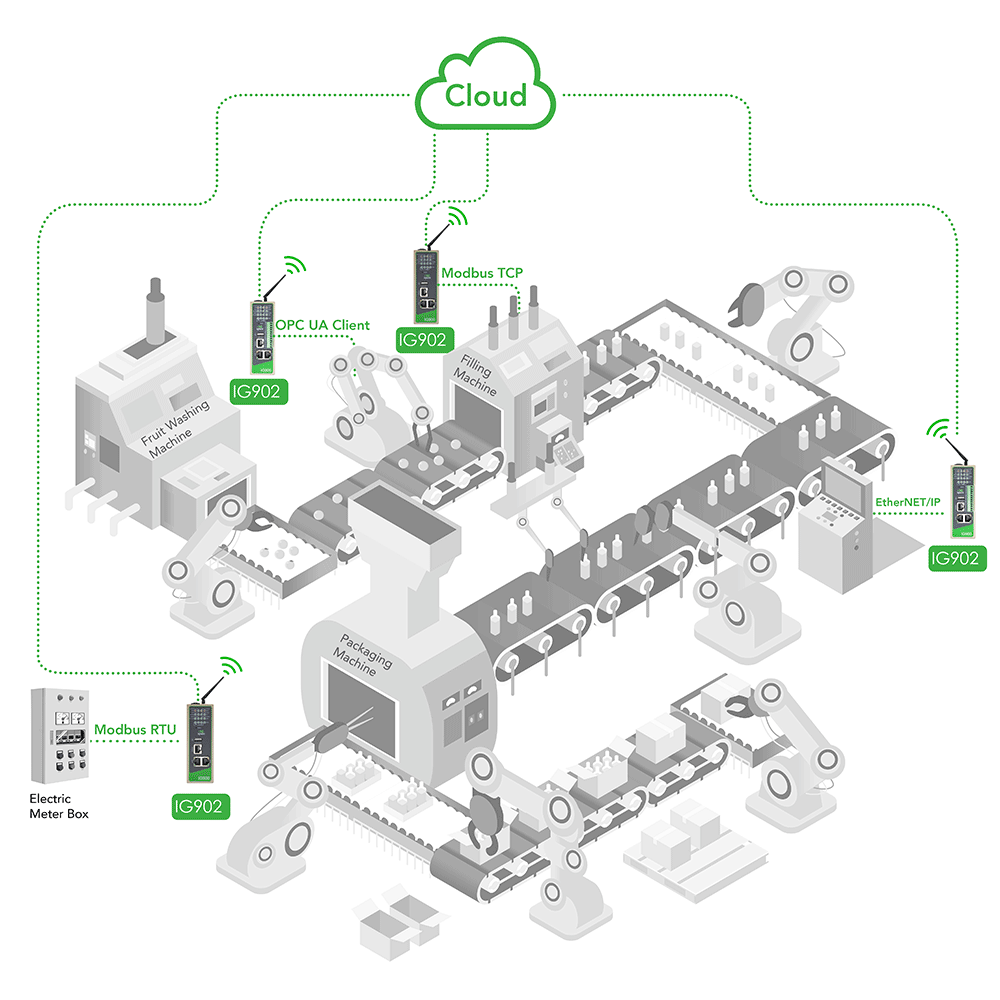

In the case of beverage production line, the IG902 edge gateway addresses the problems of industrial data collection from these aspects:

Different production links in the beverage's automated production line need different machines for their respective process, such as the fruit clean machine, the crusher, the filling machine, the packaging machine, etc. The edge computing gateway acquires operation and production efficiency data of the machinery (e.g. Profinet protocol + SMS alarm app).

Why InGateway902?

Related Product

| ||

InGateway902 | IoT Edge Gateway | Cellular Gateway |