Concrete Mixing Equipment Remote Monitoring Solution

Background

The technical performance of concrete mixing equipment of batch plants can directly affect the quality and service life of the construction projects. Concrete batch plants need to perform routine maintenance to timely detect, maintain and repair any defective parts of the mixing equipment, to reduce damage and prevent equipment from being unable to perform normal production operations. The fault elimination and maintenance of concrete mixing equipment were traditionally done by local service departments of the manufacturer, or by manufacturer employees sent to the site. This will not only bring after-sales service costs high, but will also affect the production progress of the batch plants.

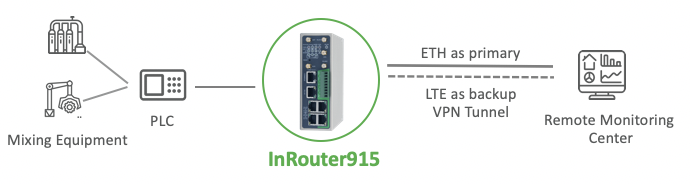

Intelligentization is the ultimate development direction of mechanical equipment, the concrete mixing equipment is no exception. InHand introduces a remote maintenance system for concrete mixing equipment based on PLC and wireless communication technology, using InHand 4G industrial router IR915. The maintenance staff can perform remote diagnosis, early warning and maintenance of the mixing equipment in real time while away from the production site.

InHand Reomte Monitoring Solution

The monitoring system of concrete mixing equipment consists PLC, edge computing gateway InRouter915 and cloud monitoring center.

Advantages

InRouter900 gateway:

Related Product

| ||

InRouter900 | Industrial Cellular Routers |